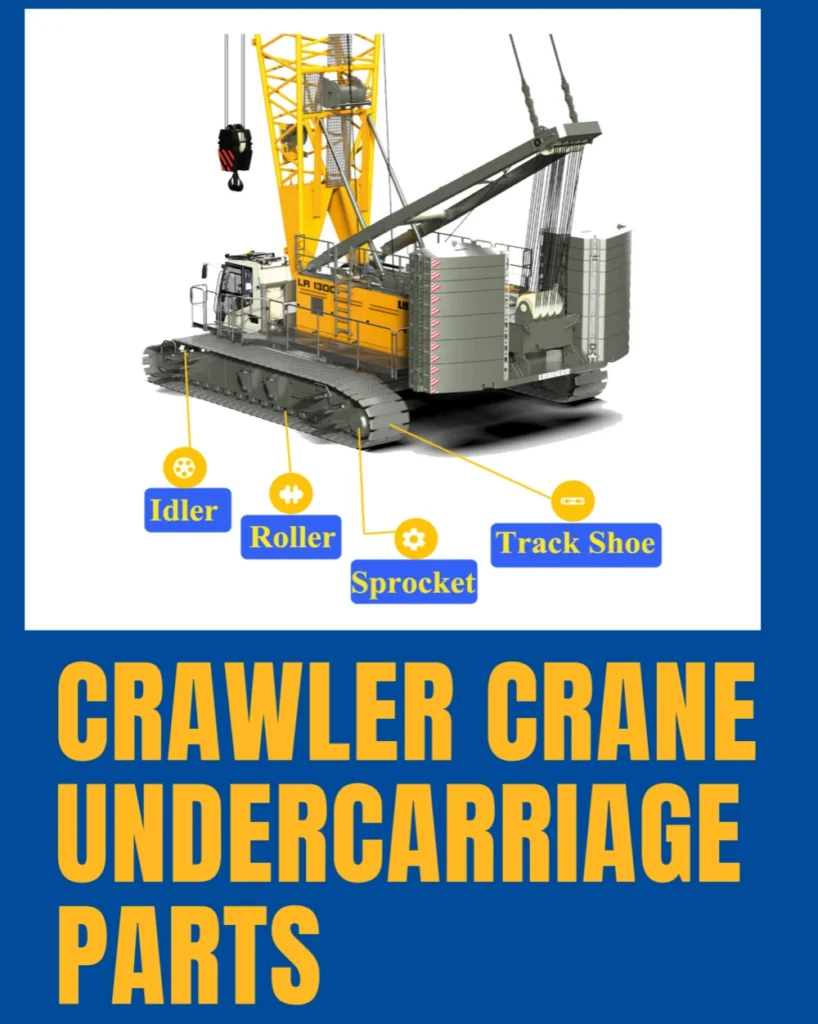

The undercarriage of a Liebherr crawler crane is the unyielding foundation upon which immense lifting power and mobility are built. It’s a complex system of Liebherr crawler crane undercarriage parts—track chains, rollers, idlers, sprockets, and shoes—that bears the entire weight of the machine and transmits its powerful drive. However, this critical assembly is also subjected to immense stress, abrasion, and wear on every job site. Ignoring the early signs of worn undercarriage can lead to catastrophic failure, unplanned downtime, and exorbitant repair costs.

Proactive inspection and timely intervention are not just best practices; they are essential for profitability and safety. This guide will walk you through the five most critical warning signs that your crane’s undercarriage needs attention and provide a clear action plan for using Liebherr undercarriage parts to ensure maximum longevity and performance.

Why Undercarriage Health is Non-Negotiable

Before diving into the signs, it’s crucial to understand the stakes. A failing undercarriage doesn’t just stop the crane; it can cause a domino effect of damage to other components. The cost of replacing a full set of crawler crane undercarriage parts is significant, but it pales in comparison to the cost of project delays, missed deadlines, and major mechanical overhauls due to neglect. Regular crawler crane undercarriage inspection is your first and most effective line of defense.

Warning Sign 1: Abnormal Wear on Crawler Shoes (Pads)

The crawler shoes are the direct point of contact with the ground, and their wear pattern is a telling diagnostic tool.

What to Look For: Don’t just measure thickness. Look for unusual wear patterns. Are the shoes wearing thin at an angle or developing a sharp, jagged “hook” on the end? This asymmetric wear often indicates misalignment or issues with the track tension. Another key indicator is excessive wear on the grouser (the protruding tread) height compared to the base material.

What it Means: Angled wear suggests that the track is not running true, which places undue stress on the track chain and rollers. Worn, hooked pads provide significantly reduced traction and stability, increasing the risk of slippage on slopes and under load.

The Implication: Continuing to operate with severely worn shoes accelerates the wear on every other component in the system. It’s a clear signal that a full crawler crane undercarriage inspection is needed to identify the root cause.

Warning Sign 2: Elongated Track Chain & Excessive Sag

The track chain links articulate under enormous pressure and will naturally elongate over time.

What to Look For: The most reliable method is to measure the track chain pitch. Consult your Liebherr manual for the exact specification, but a common rule of thumb is that replacement is necessary when elongation exceeds 3%. A simpler, visual check is to look at the sag between the front idler and the top carrier roller. Excessive sag (again, check manual specifications) is a primary symptom of an elongated chain.

What it Means: An elongated chain no longer meshes correctly with the sprocket. This causes a grinding effect, rapidly wearing down the sprocket’s teeth. It also increases the impact load on rollers and idlers.

The Implication: Running an elongated chain will quickly destroy a perfectly good sprocket, turning a single-component replacement into a far more expensive repair job.

Warning Sign 3: Seized or Noisy Track Rollers and Carrier Rollers

Rollers guide the track and distribute the crane’s weight. They are designed to spin freely.

What to Look For: During operation, listen for grinding or squealing noises from the undercarriage. Visually, during inspection, look for rollers that are not turning while the track moves. Check for visible damage, flaking metal, or significant oil leaks from their seals.

What it Means: A seized or damaged roller acts like a brake, grinding against the track chain instead of rolling with it. This creates intense, localized heat and friction, rapidly wearing out the chain bushings and the roller itself.

The Implication: A single failed roller can cause a noticeable increase in fuel consumption due to drag and will create a hot spot that prematurely wears a specific section of your expensive track chain.

Warning Sign 4: Hooked or Pointed Sprocket Teeth

The drive sprocket is the heart of the undercarriage drive system. Its condition is a direct reflection of the health of the track chain.

What to Look For: New sprocket teeth have a squared or slightly rounded profile. The critical warning sign is when these teeth become pointed, sharp, or develop a distinct “hook” or concave shape on their driving side.

What it Means: This pattern is almost exclusively caused by running an excessively elongated track chain. The chain rides higher on the sprocket, causing contact on the tip of the tooth instead of the root, gradually bending the metal forward and wearing it down.

The Implication: A hooked sprocket and an elongated chain must always be replaced as a matched set. Installing a new chain on a worn sprocket (or vice versa) will cause the new part to be destroyed in a very short time due to the mismatched engagement.

Warning Sign 5: Uneven Travel or Loss of Power

Operators are often the first to notice performance issues.

What to Look For: The crane may pull to one side during travel, require more power to move, or seem generally sluggish. You might hear the engine laboring more than usual to drive the tracks.

What it Means: This symptom can be a culmination of several issues: seized rollers creating drag, incorrect track tension, or significant internal wear within the final drive motors themselves, potentially caused by the increased strain from a failing undercarriage.

The Implication: This is a critical sign that efficiency has plummeted and the machine is under severe stress. Immediate inspection is required to prevent further damage.

Your Action Plan: The Guide to Replacement

Upon identifying any of these warning signs, your next steps are critical.

Complete Inspection: Have a certified technician perform a thorough inspection to assess all Liebherr crawler crane undercarriage parts and identify every component that requires service.

Choose Liebherr Parts: This is the most important decision. Supply the right information on your crane parts to the supplier.

Professional Installation: Proper installation and tensioning are key to longevity. Rely on experienced technicians to ensure the job is done right.

Conclusion: Don’t Wait for a Breakdown

Your Liebherr crawler crane is a capital asset designed for decades of reliable service. Protecting that investment starts with proactive maintenance of its foundation. By understanding these 5 critical warning signs of undercarriage wear and committing to Liebherr parts for replacement, you ensure maximum uptime, lower total operating costs, and the unwavering reliability that your projects demand.

Is your crane showing these signs? Don’t risk costly downtime. Contact our undercarriage experts today for a consultation, detailed pricing on Liebherr undercarriage parts, and access to our comprehensive technical support. Let us help you keep your crane moving safely and efficiently.