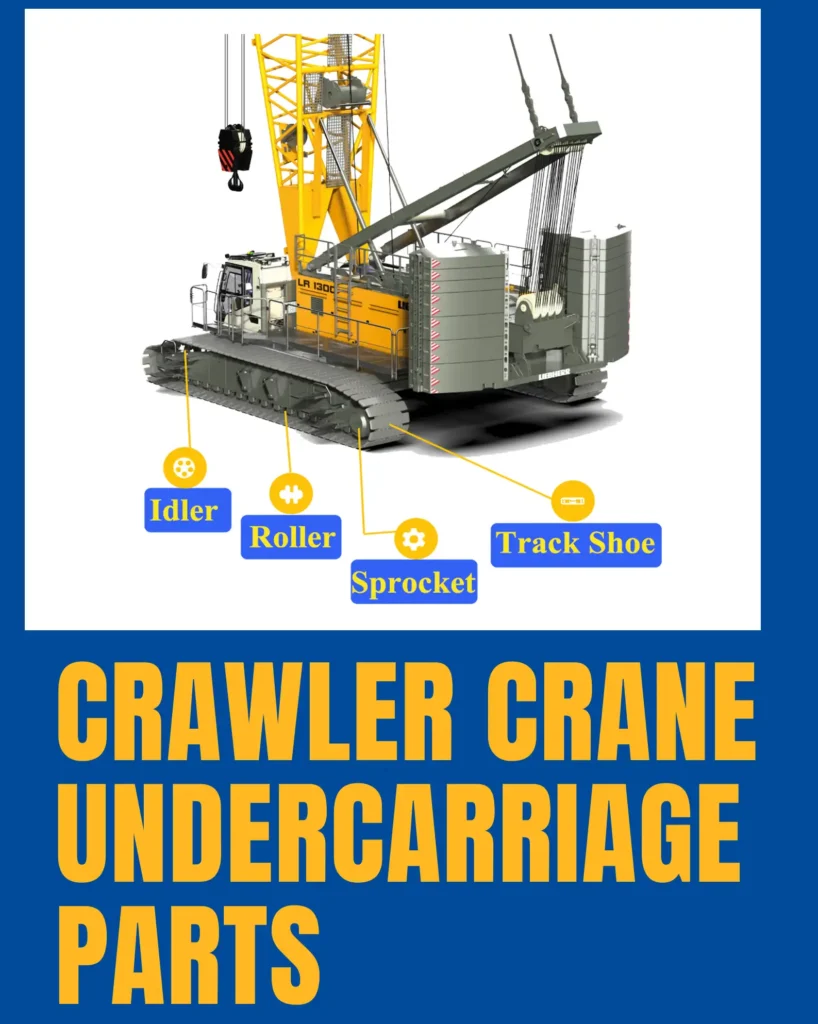

Selecting the correct undercarriage parts for your Liebherr LR1600 crawler crane is critical. It ensures machine performance, job site safety, and cost control. The right parts reduce downtime and extend crane life. This guide explains how to choose the best undercarriage components for your Liebherr LR1600 crane. It covers key factors like material, design, and supplier selection.

Using quality Liebherr LR1600 Crane Undercarriage Parts protects your investment. It avoids premature wear and system failures. We will discuss how to pick the best track shoes, rollers, and drive wheels. We also share tips for finding reliable parts suppliers.

1. Focus on Material and Build Quality

The material used in Liebherr LR1600 Crane Parts greatly affects durability. Not all steel offers the same strength.

Choose parts made from high-strength alloy steel. This material resists wear and handles heavy loads. It is ideal for various kinds of job conditions. Look for heat-treated components. Hardened surfaces last longer under stress.

For example, the Liebherr LR1600 crane track shoe must be strong and well-designed. A good track shoe design adds strength and reduces bending.

2. Precision Manufacturing Matters

Precision manufacturing ensures parts fit correctly. It prevents early wear and system issues.

For example, an LR1600 track roller must have exact dimensions. Even small size errors can cause misalignment. This leads to uneven wear and potential failure.

The top roller must also be perfectly round and balanced. It should spin smoothly under load. A poorly made roller increases friction. It can overheat and damage the track chain.

The drive wheel needs precise gear cutting. Its teeth must match the track chain exactly. An incorrect tooth shape causes fast wear and noisy operation.

3. Check for Certifications and Testing

Always choose parts that meet quality standards. Reputable manufacturers test their products thoroughly.

Look for ISO certification. This shows the supplier follows international quality systems. Parts should also have material certificates. These documents confirm the steel grade and hardness.

Some companies test their Liebherr LR1600 Crane Undercarriage Parts under real conditions. They run simulations to mimic heavy use. This proves part of the reliability before you buy.

4. Compare OEM and Aftermarket Options

You have two main choices: OEM parts and aftermarket parts. OEM parts come from Liebherr. Aftermarket parts are made by other companies.

OEM parts offer a perfect fit and performance. But they often cost more.

High-quality aftermarket parts can be a good alternative. Many offer similar performance at a lower price. Look for suppliers who specialize in Liebherr LR1600 Crane Parts. They understand the exact needs of your machine.

Always avoid cheap, low-quality imitations. They may save money first. But they often lead to more repairs and downtime later.

| Feature | OEM Parts | Aftermarket Parts |

| Source | Manufactured by Liebherr. | Produced by third-party companies. |

| Fit & Compatibility | Perfect fit and full compatibility with the LR1600 crane. | Varies by supplier; high-quality options offer a good fit, but low-quality ones may have issues. |

| Performance | Designed to meet original performance and durability standards. | Reputable suppliers offer similar performance; cheap versions often fail faster. |

| Price | Higher cost. | Generally more affordable; offers good value when quality is assured. |

| Quality & Materials | Uses high-grade materials and follows strict manufacturing standards. | Quality varies: trusted suppliers use good materials. |

| Warranty & Support | Backed by Liebherr’s official warranty and service support. | Warranty depends on the supplier; reliable brands offer solid guarantees. |

| Ideal For | Customers prioritize precision, longevity, and full warranty coverage. | Budget-conscious buyers who choose trusted aftermarket suppliers specializing in Liebherr crane parts. |

5. Find a Reliable Supplier

Knowing where to buy Liebherr LR1600 Crane Undercarriage Parts is just as important as what to buy.

Choose a supplier with a strong reputation. They should have positive customer reviews. They should offer technical support. Good suppliers help you choose the right parts. They provide advice on installation and maintenance.

A reliable supplier also stocks a wide range of parts. This includes everything from the Liebherr LR1600 crane track shoe to the drive wheel. You get all parts from one source. It makes maintenance easier.

Also, check the supplier’s warranty policy. A good warranty shows the supplier trusts their product quality.

6. Think Long-Term: Maintenance and Compatibility

How to Choose Liebherr LR1600 Crane Undercarriage Parts also involves planning for the future.

Choose parts that are easy to maintain. For example, some rollers have sealed lubricant. They need less frequent service.

Also consider part compatibility. Mixing old and new parts can sometimes cause issues. When replacing multiple parts, it is often best to use a matched set. This ensures even wear and smooth operation.

Keep records of part replacements and service dates. This helps in planning future maintenance. It also maintains your machine’s value.

Conclusion: Choose wisely, invest wisely

Selecting the right undercarriage parts for your Liebherr LR1600 is a smart decision. It ensures safety, reduces downtime, and saves money over time.

Remember to focus on material quality, manufacturing precision, and supplier reliability. Whether you need an LR1600 track roller, a top roller, or a drive wheel, always choose quality over price.

If you are unsure where to buy Liebherr LR1600 Crane Undercarriage Parts, start with trusted suppliers. Look for those with experience, good customer service, and solid warranties.

By making careful choices, you keep your crane running strong. You protect your investment and support your project’s success.