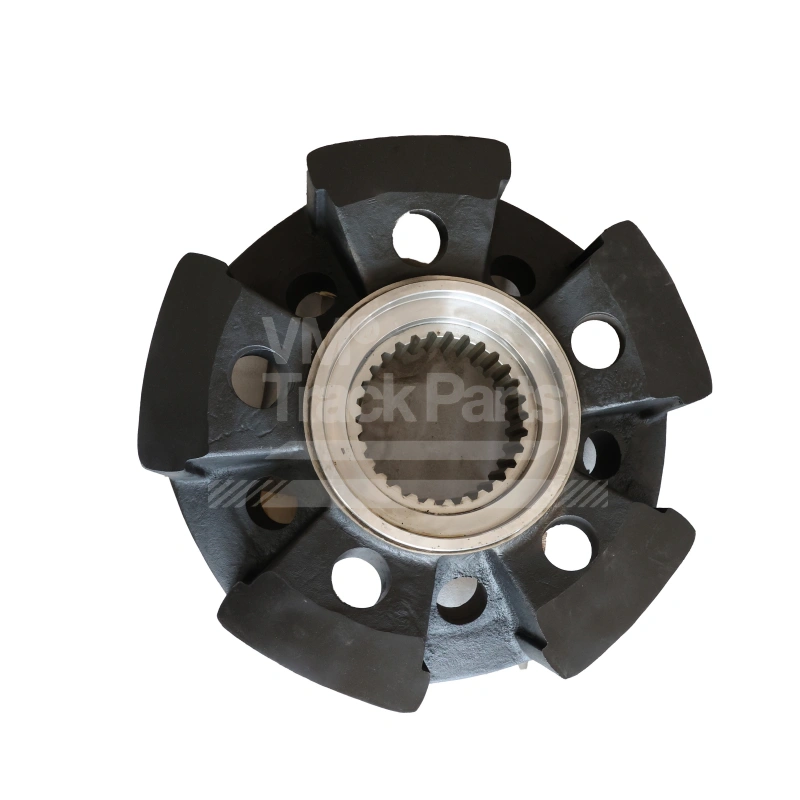

Liebherr 385213314 Sprocket | VM®: Forged 40Mn2 steel/copper bushings. Quenched & tempered. ISO9001/CE certified. 2500hr/1yr warranty. 26+ years of manufacturing. Inquire Today!

Parts Information

| Model | Liebherr LR11350 |

| Material | 35SiMn |

| Bushing | 100% Copper Alloy Bushing |

| Technology | Forging |

| Heat Treatment | Quenching and Tempering |

| Color | Black / Customer Requirement |

| Warranty | 2500 Working Hours / One Year |

| Certification | CE, ISO9001 |

| Origin | China |

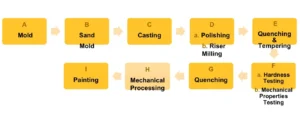

Production Process of Liebherr 385213314 Sprocket

Hot Sale Liebherr Crane Parts

| 749065214 | 388291208 |

| 925067508 | 925197608 |

| 971195808 | 971195908 |

HS852HD, HS855HD, HS895, HS833HD, HS843, HS853HD/VRM, HS882, HS883, HS872, HS885, HS895HD, LR1100, LR1160, LR1200, LR1250, LR1280, LR1300, LR1350, LR1400, LR1400-2, LR1550, LR1600, LR1600-2, LR1650, LR1750, LR11000, LR11350, LTR1100, LTR1220, LR1130, LTR1060, LB28, R974, HS830, HS832HD, HS840, HS841, HS842HD, HS851, HS851HD, HS870, HS871, HS873HD, HS993, HS8200HD, HS875HD, HS885HD, HS8100HD.

Warehouse

Packing&Shipping

Maintenance and replacement:

Wear: The drive wheel is one of the most worn parts in the chassis system (it wears against the track chain pin sleeve). The main manifestations of wear are sharpening, thinning, hooked deformation (“tooth tip hooking”), depression at the root of the tooth, and even broken teeth.

Replacement time: When the tooth wear exceeds the limit specified by the manufacturer (usually measuring the tooth height or observing the change in tooth shape), or when there is damage such as broken teeth and cracks, the drive wheel must be replaced. It is usually recommended to check and consider replacing the drive wheel at the same time as replacing the track chain link. Replacing only the track without replacing the severely worn drive wheel will accelerate the wear of the new track (called “track eating”).

Replace in pairs: The drive wheels must be replaced in pairs (left and right sides) at the same time. Different wear conditions of the new and old drive wheels will cause the machine to deviate from the track, inconsistent walking speeds on both sides, and accelerate uneven wear of other chassis parts.

Track matching: Extremely important! When replacing the drive wheel, it must be ensured that it is fully compatible with the specifications of the current track chain link (pitch, chain pin sleeve size). If the track links are also severely worn, the track assembly (including the links, chain pins, chain pin sleeves, and track shoes) usually needs to be replaced at the same time.

Installation requirements: During installation, ensure that the travel motor output shaft and mounting flange are clean, tighten the bolts/nuts strictly according to the specified torque and sequence, and use the recommended locking glue (if necessary). After installation, check whether the travel is smooth and without abnormal noise.

Reviews

There are no reviews yet.